Fixed ZAM ground solar PV mounting structure

PRO.FENCE design ZAM solar mount ground mounting system for installation of large-scale PV project especially require for high anti-corrosion and better strength agains high wind loading.

Why ZAM material?

- Better corrosion resistance

Tha main structure is made of ZAM material that perform better corrosion resistance as per SGS report of Salty Spray Test. The addition of AI, Mg elements further enhance the corrosion resistance in dozen times.

- Better abrasive resistance

It has feature of abrasive resistance that could reduce the damage of coating wear and make the finished products smooth.

- Higher cost-effective

The technology imported from Japan has been developed in China for many years and can be supplied in lower cost.

Specification

| Install Site | Open terrain |

| Adjustable angle | Up to 60° |

| Wind speed | Up to 46m/s |

| Snow load | Up to 50cm |

| Clearance | Up to request |

| PV module | Framed, Unframed |

| Foundation | Ground screws, Concrete base |

| Material | ZAM |

| Module Array | Any layout up to site condition |

| Standard | JIS C8955 2017 |

| Warranty | 10 years |

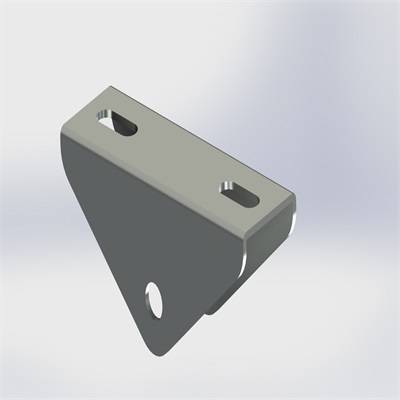

Components

.jpg)

.jpg)

Rail

Standing Post

Splicing

Screw Plies

Reference

FAQ

1. How many types of ground solar PV mount structures we supply?

Fixed and adjustable ground solar mounting. All shapes structures could be offered.

2. What materials you design for PV mounting structure?

Q235 Steel, Zn-Al-Mg, Aluminum Alloy. Steel ground mounting system has absolutely price advantage.

3. What’s advantage compare with other supplier?

Small MOQ acceptable, Raw material advantage, Japanese Industrial Standard, professional engineering team.

4. What info are required for a quotation?

Module data, Layout, condition at site.

5. Do you have a quality control system?

Yes, strictly as per ISO9001, full inspection before shipment.

6. Can I have samples before my order? What’s the minimum order quantity?

Free mini sample. MOQ Depends on products, please feel free to contact us for any inquires.