Select your chain link fence fabric based on these three criteria: gauge of wire, size of mesh and type of protective coating.

1. Check the gauge:

Gauge or diameter of wire is one of the most important factors – it helps tell you how much steel is actually in the chain link fabric. The smaller the gauge number, the more steel, the higher the quality and the stronger the wire. From lightest to the heaviest, common gauges for chain link fence are 13, 12-1/2, 11-1/2, 11, 9 and 6. Unless you are building a temporary chain link fence, we recommend your chain link fencing to be between 11 and 9 gauge. 6 gauge is typically for heavy industrial or specialized uses and the 11 gauge is a heavy residential chain link that stands up better to kids and pets.

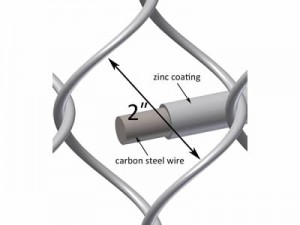

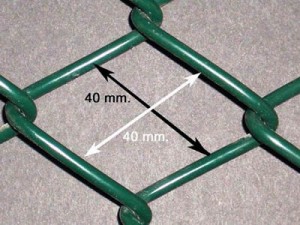

2. Measure the mesh:

Mesh size tells you how far apart the parallel wires are in the mesh. That is another indications of how much steel is in the chain link. The smaller the diamond, the more steel is in the chain link fabric. From largest to smallest, typical chain link mesh sizes are 2-3/8″, 2-1/4″ and 2″. Smaller chain link meshes such as 1-3/4″ is used for tennis courts, 1-1/4″ for pools and higher security, the mini chain link meshes of 5/8″, 1/2″ and 3/8″ are also available.

3. Consider the coating:

Several types of surface treatments help protect and beautify and enhance the look of steel chain link fabric.

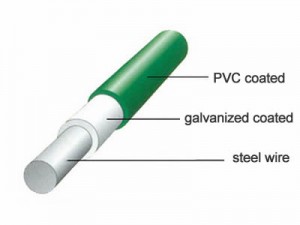

- The most common protective coating for chain link fabric is zinc. Zinc is a self-sacrificing element. In other words, it dissipates while protecting the steel. It also offers cathodic protection which means that if the wire is cut, it “heals” the exposed surface by developing a white oxidation layer that prevents red rust. Typically, galvanized chain link fabric has a 1.2-ounce per square foot coating. For specification projects requiring greater degrees of longevity, 2-ounce zinc coatings are available. The longevity of the protective coating is directly related to amount of zinc that is applied.

- There are two primary ways that chain link fabric is galvanized (coated with zinc). The most common is Galvanized After Weaving (GAW) where the steel wire is formed into chain link fabric first and then galvanized. The alternative is Galvanized Before Weaving (GBW) where the strand of wire is galvanized before being formed into the mesh. There is some debate over which is the best method. GAW ensures that all of the wire is coated, even the cut ends, and galvanizing the wire after is formed also tends to increase the tensile strength of the finished product. GAW is typically the method of choice for the larger manufacturers, since it requires a higher level of manufacturing expertise and capital investment than simply weaving the wire, and it yields efficiencies only available wit this method. GBW is a good product, provided it has a diamond size, weight of zinc coating, gauge and tensile strength.

- You also will find aluminum-coated (aluminized) chain link wire on the market. Aluminum differs from zinc in that it is a barrier coating rather than a sacrificial coating and as a result cut ends, scratches, or other imperfections are prone to red rusting in a shorter period of time. Aluminized is best suited where esthetics is less important than structural integrity. Another metallic coating sold under various trade names that uses a combination zinc-and-aluminum, uniting the cathodic protection of zinc with the barrier protection of aluminum.

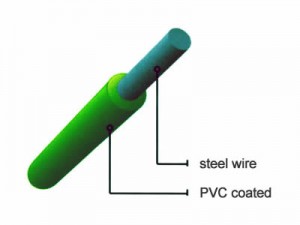

4. Want color? Look for polyvinyl chloride applied in addition to the zinc coating on the chain link. This provides a second kind of corrosion protection and blends aesthetically with the environment. These color coatings come in following principle coating methods.

Electrostatic powder coating is a method in which paint is charged with a machine and then applied to a grounded object using static electricity. This is a coating method that forms a coating film by heating in a baking drying oven after coating. Widely used as a metal decoration technology, it is easy to obtain a high-thickness coating film, and it has a beautiful finish, so you can choose from various colors.

Powder dip coated is a method in which a perforated plate is placed at the bottom of a paint container, compressed air is sent from the perforated plate to allow the paint to flow, and a preheated object is immersed in the flowing paint. The paint in the fluidized bed is fused to the object to be coated by heat to form a thick film. The fluid immersion coating method usually has a film thickness of 1000 microns, so it is often used for corrosion-resistant coating

Be sure that you understand both the gauge of the finished product and the steel core wire. a product that is produced in an 11 gauge finished diameter which, with most coating processes, means that the steel core is very light – not recommended for normal installations of 1-3/4″ to 2-38″ diamond size mesh.

Post time: Dec-15-2021