Did you have a solar ground mounting project located in very soft silty clay, such as paddy land or peat land? How would you construct the foundation to prevent sinking and pull out? PRO.ENERGY would like to share our experience through the following options.

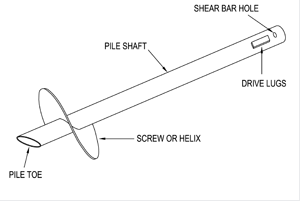

Option1 Helical pile

Helical piles consist of a serious of helix-shaped circular plates that are attached to a slender steel shaft. It is a popular solution for relatively low-capacity, removable or recyclable foundations supporting light structures for example solar ground mounting system. When specifying a helical screw pile, a designer must choose the active length and the helical plate spacing ratio, which are governed by the number, spacing and size of the individual helices.

Helical pile also has potential application for the foundation construction on soft soils. Our engineer calculate the helical pile under compressive load using finite element limit analysis and found the number of helical plate with the same diameter increased bearing capacity meanwhile the larger helical plate is, the more capacity increased.

Option2 Soil-cement

Applying a soil-cement mixture to treat soft soil is an effective solution and is being widely applied in many countries around the world. In Malaysia, this method has also been used in solar ground mounting projects, especially in areas with Soil Value N less than 3 such as coastal areas. The soil-cement mixture is made up of natural soil and cement. When cement is mixed with soil, the cement particles will react with water and minerals in the soil, forming a hard bond. The polymerization of this material is equivalent to the curing time of cement. Additionally, the amount of cement needed is reduced by 30% while still ensuring uniaxial compressive strength compared to when using only cement.

I believe the solutions mentioned above are not the only options for soft soil construction. Are there any additional solutions that you can share with us?

Post time: Apr-09-2024